Combi-Block (Blowing-Filling-Capping) Water Production line

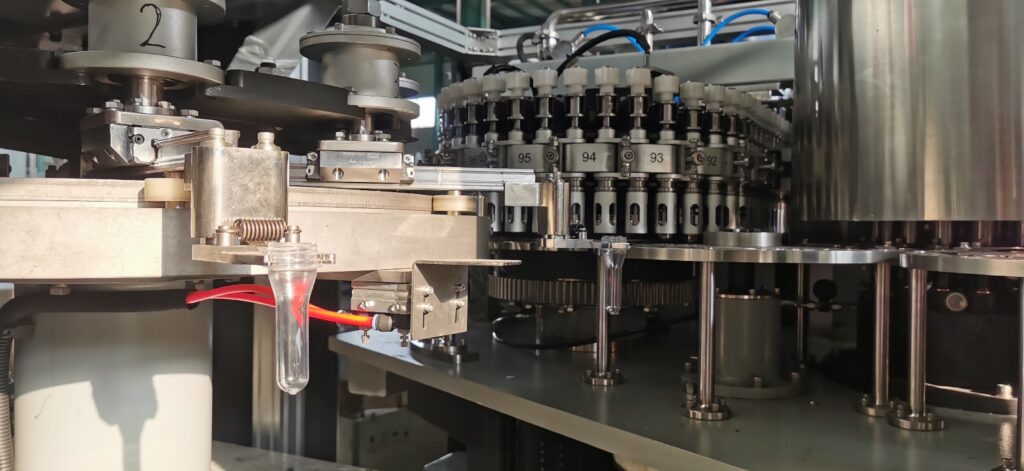

3-in-1 Automatic Beverage Filling Machine (Blowing–Filling–Capping Combiblock)

The 3-in-1 automatic beverage filling machine is a cost-effective and environmentally responsible solution that integrates bottle blowing, filling, and capping into a single compact system for PET bottle beverage production.

By combining these three processes in one Combiblock design, the system significantly reduces floor space requirements, minimizes bottle handling, lowers contamination risk, and improves overall production efficiency—making it an ideal choice for modern beverage plants.

Production Capacity

- Capacity Range: 8,000 – 81,000 bottles per hour

- Applicable Bottle Sizes: 200 ml – 1,500 ml PET bottles

- Suitable for water, carbonated soft drinks, juices, and other beverages (configuration dependent)

Key Technical Features

Advanced Servo Stretching System

- Tailor-made servo stretching technology

- Adaptable to PET preforms with various stretching ratios

- Enables variable production speeds with high-precision positioning

- Ensures consistent bottle quality and optimized material usage

High Cleanliness Design

- Optional ionized de-duster system effectively removes dust and particles from preforms

- Enhances container cleanliness before bottle forming

- Supports higher hygiene standards for beverage packaging

Reliable Filling Valve System

- Filling valve designed with a clean, compact, and safe valve body

- Ensures stable filling accuracy and smooth operation

- All product-contact parts are manufactured from high-quality, food-grade materials

- Guarantees product safety, durability, and long service life

Key Advantages

✔ Integrated blowing–filling–capping design

✔ Reduced footprint and lower investment cost

✔ Improved hygiene and reduced contamination risk

✔ High efficiency with stable output at high speeds

✔ Flexible adaptation to different bottle sizes

✔ Energy-saving and environmentally friendly operation

Ideal Applications

- Bottled drinking water

- Carbonated soft drinks (CSD)

- Juices and functional beverages

- Still beverages in PET bottles